MVD-6kw microwave vacuum hazardous waste reduction processor

2020/6/11

• Brand: WOLONG

• Operation mode: PLC adjustable program control

• Product category: microwave vacuum low-temperature dryer

• Model: MVD-6kw

• Additional function: automatic shutdown after drying

• Sales scope: Asia Pacific

• Material: 304 stainless steel

• Heating method: complete microwave heating

• Auxiliary unit: equipped

• Origin: Shanghai, China

• Structure style: integrated one-piece structure

* Energy mode: full electric energy

MVD-6kw microwave vacuum hazardous waste reduction treatment machine is specially used to dry and treat the sludge after plate and frame pressure filtration for final thorough drying. The reduction of solid waste generally refers to the reduction of the quantity or harmfulness of solid waste, which includes two meanings, one is the reduction of quantity, the other is the reduction of the harmfulness of solid waste to the environment.

Through the reduction treatment of MVD-6kw microwave vacuum hazardous waste reduction processor, we can effectively separate the pH and reduce the harm of hazardous waste to the environment.

The implementation of the solid waste reduction service must pay attention to the source control, that is to say, the work should consider "energy conservation, consumption reduction, pollution reduction and efficiency increase" from the selection of process and raw materials. The cleaner production audit is an effective service form. It refers to continuously taking measures such as improving design, using clean energy and raw materials, adopting advanced technology and equipment, improving management and comprehensive utilization to reduce pollution from the source, improve resource utilization efficiency, reduce or avoid the generation and discharge of pollutants in the process of production, service and product use, so as to reduce or eliminate the harm to human health and the environment.

MVD-6kw microwave vacuum hazardous waste reduction treatment machine is a new comprehensive drying technology design scheme that combines the three technologies of microwave heating drying, vacuum drying and dynamic operation of materials, giving full play to the advantages of microwave drying, vacuum and dynamic materials.

Due to the low boiling point of water molecules in the vacuum environment, the material drying temperature is very low, which does not affect the color and composition of the material, especially the energy of microwave is directly acting on the material, and does not need heat conduction, so the material drying efficiency is high. This method has the advantages of low temperature, fast drying rate, good quality, etc. when drying the material, and the efficiency is far higher than the traditional vacuum drying equipment. The MVD-6kw microwave vacuum hazardous waste reduction treatment machine is different from incineration. The microwave solid waste reduction treatment technology is to use microwave energy to separate the water and organic vapors from the high molecular weight organic matter under the condition of oxygen or oxygen deficiency.

General use:

1. The initial water content of the material is below 80%.

2. The dryness is required to be within 0.1% - 20%.

3. The drying temperature is within 20-120 ℃.

4. The material is powder or granular, and there is no requirement on the appearance after drying.

5. It can meet the intermittent operation performance.

Common types are:

1. Drying temperature: 10-100 ℃.

2. High vacuum: ≥ -0.098-0.099Mpa.

3. Recovery of evaporation: more than 90% of the evaporated gas is effectively recovered.

4. Multi-purpose machine: can dry various materials.

5. Condensation temperature: - 20 ℃. It is comparable to the freeze-drying effect.

Other special purposes:

Microwave vacuum wall breaking:

Microwave vacuum low-temperature drying dehydration:

Microwave vacuum low-temperature sterilization:

Microwave vacuum carbonization:

Microwave vacuum removal of pesticide residues:

Microwave vacuum expansion:

Microwave vacuum desulfurization and deacidification:

Dried fruit of microwave vacuum low temperature drying machine equipment scope of application:

Can undertake dehydration dry at low temperature in most fruits and vegetables, including banana chips, jackfruit, figs, lotus seed, red jujube and jujube, cashews, walnuts and shell walnuts, gingko shell, fructus momordicae, chickpeas, wolfberry fruit, fruit products such as low temperature and dry.

1, material in 80% of the initial water cut.

2, dry degree requirements within 1% to 20%.

3, the drying temperature within 20-120 degrees.

4, material for powder or granular, after drying to form without request.

5, conforms to the intermittent operating performance.

1. Low drying temperature - lower than 30 ℃,

2. Recoverable evaporation ---- Recoverable condensable matter above 0 ℃.

3. It can evaporate and separate the residues of organic pesticides and sulfides inside the material -- after reduction, it can reach PPM level.

4. The vacuum degree is high when the equipment is working -- above -0.098.

5. Take dry rose as an example, three products can be obtained at the same time - sulfur free rose dry flower, super rose cell fluid and super rose essential oil.

6. The designed service life of the equipment is more than 10 years.

Under vacuum conditions, heating the object can make the water inside the object evaporate without temperature rise. Due to the difficulty of air convection and heat transfer under vacuum conditions, the only way to provide heat energy for materials is to rely on heat conduction. The conventional vacuum drying method has a slow heat transfer speed, low efficiency, and difficult temperature control. The heated material will also produce internal and external temperature difference. Microwave heating is a kind of radiation heating, which is the direct interaction between microwave and objects, so that they are heated inside and outside at the same time, without convection or conduction to transfer heat, so the heating speed is fast, the drying efficiency is high, and the drying quality is high.

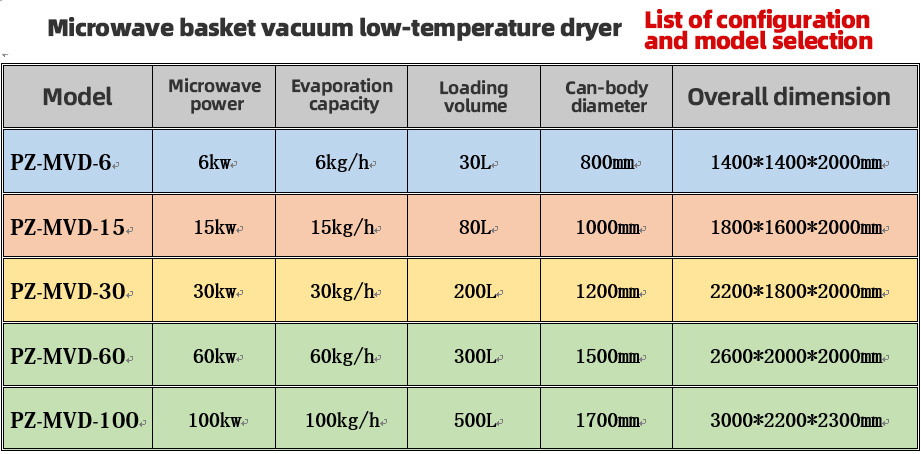

Rated input power S: 10kW

Microwave output power P: ≤ 6KW

Single loading volume L: 50 L/time

Drying and dehydration efficiency Q: 5-6kg/h

Temperature control accuracy C: ± 3 ℃

Microwave leakage detection p: 2MW/cm2 ≤ 5mw (national safety standard

Rotation speed of basket V: 0-15 rpm

Overall dimension of equipment L: 2600 * 1150 * 2100mm

Sludge solid waste after plate and frame pressure filtration, domestic waste after crushing and extrusion, and kitchen waste after crushing.

Traditional Chinese medicine slices: Fritillaria, Huai yam, ginger slices, gastrodia elata slices, siraitia grosvenorii, dried ginger, astragalus, coptis chinensis, salvia miltiorrhiza, polygonum multiflorum, licorice, atractylodes macrocephala, raw rehmannia, angelica, betel nut, panax notoginseng slices, cistanche deserticola, etc

Extract: expanded donkey-hide gelatin powder, expanded drying of traditional Chinese medicine extract, animal and plant extracts, etc

Dried fruit food: dried durian, dried figs, white fungus, balsam pear slices, green pepper, osmanthus, green cabbage Malantou, cauliflower, rose, mushroom, lemon slices,

Chemical synthesis: synthetic resin, natural rubber drying, bisphenol A epoxy resin, dodecylbenzene sulfonic acid, propyl p-hydroxybenzoate

Biological products: transglutaminase, Keran gum, tea polyphenols, various biological agents, fermentation engineering, low-temperature drying, etc

Youshengda Microwave Technology (Shanghai) Co., Ltd Copyright ICP:2023002225-1 Disclaimer