Expansion of Traditional Chinese Medicine Extract by Microwave Vacuum and Low Temperature Drying

2018/10/10

Under the effect of microwave vacuum low-temperature expansion drying energy, donkey-hide gelatin paste can generate heat quickly and achieve drying by water evaporation. This drying method does not need to be conducted through the medium. Microwave energy directly acts on the extract, and the surface will not appear during the drying process

The problem of hardening and drainage is difficult. The drying temperature of the extract is low, and it can maintain the efficacy. Therefore, it has the characteristics of high drying quality, fast drying speed, low production cost, energy saving, high yield, and simple operation, and meets the requirements of the extract drying.

During the drying process of donkey-hide gelatin paste, the evaporation temperature of water has a direct relationship with atmospheric pressure. The lower the atmospheric pressure, the lower the boiling point of water. At one atmospheric pressure, the boiling point of water is 100 ° C, and the true void is less than -0.098 trillion

At Pascal, the evaporation temperature of water is 30-40 ℃. Therefore, when the object is in a vacuum state, the moisture in it can evaporate at a lower temperature, making the object dry at a lower temperature.

Drying cost

The effective ingredient content of donkey-hide gelatin paste dried by MVD series microwave vacuum equipment does not change, which is higher than that of ordinary vacuum drying equipment, indicating that this drying method can effectively improve the quality of donkey-hide gelatin paste.

Low temperature+fast=high quality

Electric charge for drying 1 kg of donkey-hide gelatin paste: (calculated at 1 yuan per kilowatt-hour) only 1.0 yuan of electric charge (only equivalent to half of the operating cost of vacuum pump of ordinary vacuum equipment) 4.75 yuan of electric charge for ordinary vacuum equipment

Data comparison

Traditional donkey-hide gelatin paste drying

Oven drying temperature is high, time is long, quality is low, energy consumption is large, floor area is large

The vacuum drying temperature is higher, the time is longer, the quality is lower, the energy consumption is large, and the floor area is large

High spray drying temperature, short time, high quality, high energy consumption, large floor area

Microwave vacuum equipment covers a small area: only 35% (common vacuum drying equipment)

Large capacity: 1 set top 2-3 sets

Less investment: (under the same output) less than (ordinary vacuum drying equipment)

Conclusion:

More! Come on! OK! Province!

1. More - The output is much larger. One equipment can dry 10 kg of donkey-hide gelatin paste in one hour.

2. Fast - 40-60 minutes to dry

3. Good - good quality after drying

4. Provincial-provincial energy, investment and plant area

Comparison between microwave vacuum dryer and heat conduction vacuum drying:

1. Microwave vacuum low-temperature drying equipment combines the advantages of microwave and vacuum drying.

2. Microwave heating does not need heat conduction, which makes up for the shortcomings of conventional vacuum drying.

3. It has the advantages of high output, good quality and low processing cost.

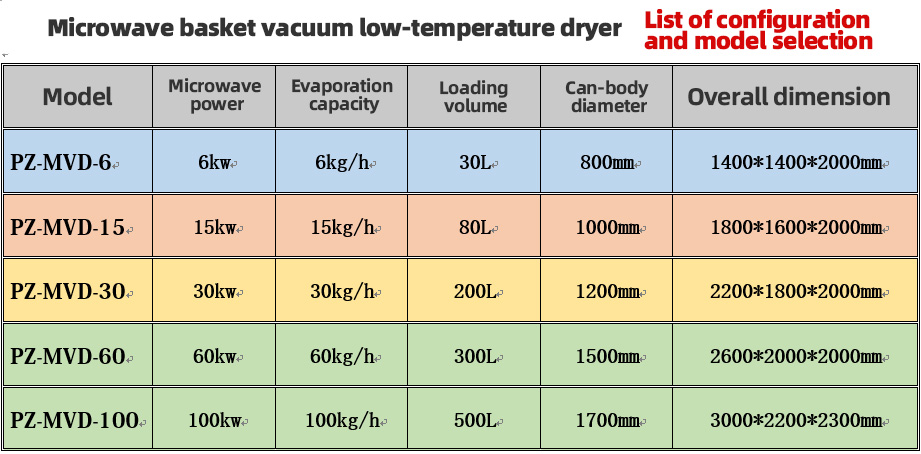

4. Microwave vacuum low-temperature drying equipment is available in continuous, tower, box and other models.

Technical features of microwave vacuum dryer:

1. Quantitative feeding under vacuum can be set freely as required.

2. The heating system can adopt microwave heating mode.

3. The drying temperature is low, and the drying can be completed at 20 ℃ − 40 ℃.

4. The hopper is made of sanitary Teflon or PP material, and operates smoothly.

5. It can be used for drying various materials such as liquid, extract, powder and granule.

6. Equipped with CIP in-place cleaning system, automatic cleaning is fast and convenient.

7. Select a new type of vacuum pump, which has been carefully designed and combined, with continuous large-capacity pumping rate and stable vacuum degree.

8. Low energy consumption, no three wastes and low noise.

9. Meet GMP certification requirements.

Rated input power S: 10kW

Microwave output power P: ≤ 6KW

Single loading volume L: 50 L/time

Drying and dehydration efficiency Q: 5-6kg/h

Temperature control accuracy C: ± 3 ℃

Microwave leakage detection p: 2MW/cm2 ≤ 5mw (national safety standard

Rotation speed of basket V: 0-15 rpm

Overall dimension of equipment L: 1450 * 1450 * 2000mm

- Related information

Youshengda Microwave Technology (Shanghai) Co., Ltd Copyright ICP:2023002225-1 disclaimer