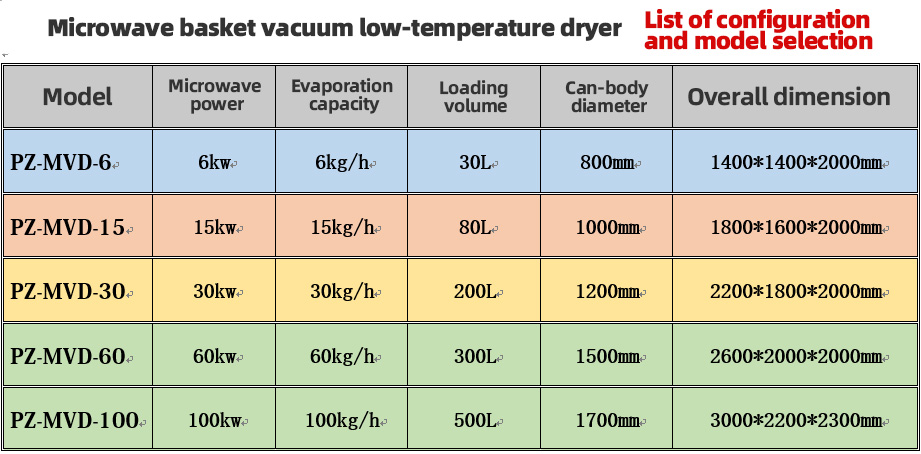

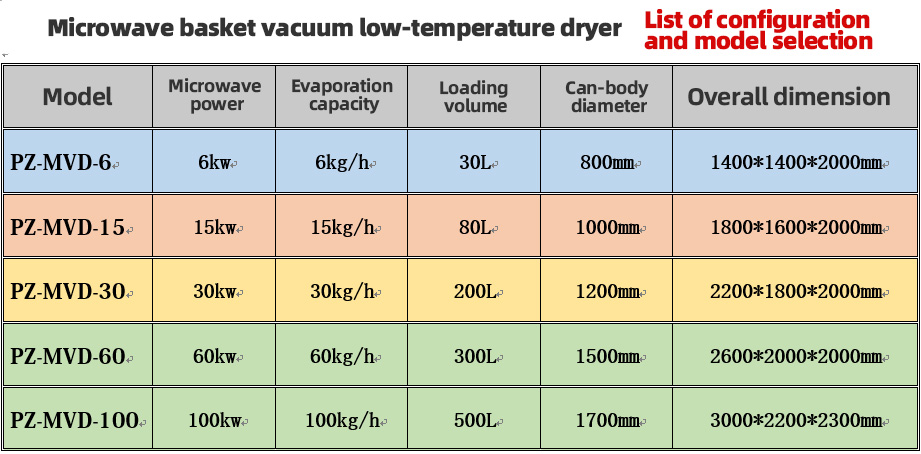

MVD-15kw microwave vacuum basket type low-temperature dryer

2017/7/24

• Brand: WOLONG

• Operation mode: PLC adjustable program control

• Product category: microwave vacuum low-temperature dryer

• Model: MVD-15kw

• Additional function: automatic shutdown after drying

• Sales scope: Asia Pacific

• Material: 304 stainless steel

• Heating method: microwave heating

• Auxiliary unit: complete set

• Origin: Shanghai, China

• Heating method: microwave heating

* Energy mode: full electric energy

MVD-15kw microwave vacuum basket drying equipment is developed to provide a new and effective low-temperature drying process for the deep processing of food, pharmaceutical, biological, chemical, new materials and agricultural by-products. Most fruits and vegetables can be dehydrated and dried at low temperature, including banana slices, jackfruit, figs, lotus seeds, red dates and jujube slices, cashews, walnut kernels and walnuts with shells, ginkgo with shells, siraitia grosvenorii, chickpea, lycium barbarum fruits, and other fruit products.

The sliced products such as lemon and balsam pear can be dried and expanded at low temperature, including volatile, flammable and explosive products such as ethanol and methanol. The evaporated products can be recovered during the drying process, which is safe, environmentally friendly and reduces environmental pollution.

General use:

1. The initial water content of the material is below 80%.

2. The dryness is required to be within 1% - 20%.

3. The drying temperature is within 20-120 ℃.

4. The material is powder or granular, and there is no requirement on the appearance after drying.

5. It can meet the intermittent operation performance.

Common types are:

1. Drying temperature: 10-100 ℃.

2. High vacuum: ≥ -0.096Mpa.

3. Recovery of evaporation: more than 90% of the evaporated gas is effectively recovered.

4. Multi-purpose machine: can dry various materials.

5. Condensation temperature: - 20 ℃. It is comparable to the freeze-drying effect.

Other special purposes:>

Microwave vacuum wall breaking:

Microwave vacuum low-temperature drying dehydration:

Microwave vacuum low-temperature sterilization:

Microwave vacuum carbonization:

Microwave vacuum removal of pesticide residues:

Microwave vacuum expansion:

Microwave vacuum desulfurization and deacidification

1. Performance of MVD-15kw microwave vacuum low-temperature dryer:

In conventional vacuum drying equipment, it is very difficult to transfer heat by convection in vacuum, which can only be conducted, with slow heating speed, long drying cycle and high energy consumption. Microwave vacuum low-temperature drying equipment adopts

Electromagnetic wave radiation energy transfer is the overall heating of the medium by microwave without other heat transfer media, which avoids the disadvantage of slow heat transfer speed. Therefore, the microwave vacuum low-temperature dryer has fast heating speed, high efficiency and greatly shortened drying cycle,

Lower energy consumption. Compared with conventional heat conduction drying technology, it can improve the work efficiency by more than four times.

2. Heating uniformity of MVD-15kw microwave vacuum low-temperature dryer:

Because microwave heating is the simultaneous heating of materials inside and outside, the temperature difference between the inside and outside of materials is small, which will not cause the inconsistent heating inside and outside of conventional heating, and greatly improve the drying quality. Easy to control: convenient for continuous

The production and automation are easy to control in time and adjust and determine the process parameters due to the characteristics of rapid adjustment of microwave power and inertia-free.

3. The product quality of MVD-15kw microwave vacuum low-temperature dryer is good:

Compared with conventional methods, the quality of processed products has been greatly improved. In addition, microwave equipment has the efficacy of disinfection and sterilization, and the product is safe and sanitary. The shelf life can be extended.

4. Technical principle of MVD-15kw microwave vacuum low-temperature dryer:

Microwave vacuum drying equipment is a new type of microwave energy application equipment combining microwave energy technology and vacuum technology. It combines a series of advantages of microwave and vacuum drying, and overcomes the long cycle and low efficiency of conventional vacuum drying

Disadvantages: In the drying process of general materials, it has the advantages of high drying yield, good quality, low processing cost, etc. The microwave vacuum drying equipment market is a combination of electronics, vacuum, mechanics, thermodynamics, program control and other disciplines

The high-tech product of the body is a new technology and process developed on the basis of in-depth research on the physical changes of substances in the drying process, internal and external heat and mass exchange, and water transfer process under vacuum conditions. Microwave vacuum

The drying equipment consists of microwave generator, vacuum drying chamber, material rotating disc, vacuum system and electronic control system.

Equipment power supply: three-phase four-wire 380V ± 10% 60Hz ± 1%

Microwave output frequency: 2450 ± 50MHz

Input apparent power: ≤ 25KVA

Microwave output power: 15KW (power adjustable)

Dehydration and drying efficiency: 12-15kg/h

Equipment vacuum strength: ≤ 1000-500pa (digital vacuum meter)

Polypropylene material box: 600 * 150 * 150mm with 12

The overall size of the equipment is about: (length × wide × High) 2500 × two thousand × 2000mm

Executive standard of microwave equipment:

Comply with the national GB/T 5959.6-2008 Safety Code for Industrial Heating Equipment

Comply with the national GB15226-1993 electrical safety standard

Comply with the national GB16798-1997 food machinery hygiene and safety standards

MVD-15kw successfully applied product catalog:

Traditional Chinese medicine slices: Fritillaria, Huai yam, ginger slices, gastrodia elata slices, siraitia grosvenorii, dried ginger, astragalus, coptis chinensis, salvia miltiorrhiza, polygonum multiflorum, licorice, atractylodes macrocephala, raw rehmannia, angelica, betel nut, panax notoginseng slices, cistanche deserticola, etc

Extract: expanded donkey-hide gelatin powder, expanded drying of traditional Chinese medicine extract, animal and plant extracts, etc

Dried fruit food: dried durian, dried figs, white fungus, balsam pear slices, green pepper, osmanthus, green cabbage Malantou, cauliflower, rose, mushroom, lemon slices,

Chemical synthesis: synthetic resin, natural rubber drying, bisphenol A epoxy resin, dodecylbenzene sulfonic acid, propyl p-hydroxybenzoate

Biological products: transglutaminase, Keran gum, tea polyphenols, various biological agents, fermentation engineering, low-temperature drying, etc

| • Brand: WOLONG | • Operation mode: PLC adjustable program control | • Product category: microwave vacuum low-temperature dryer |

| • Model: MVD-15kw | • Additional function: automatic shutdown after drying | • Sales scope: Asia Pacific |

| • Material: 304 stainless steel | • Heating method: microwave heating | • Auxiliary unit: complete set |

| • Origin: Shanghai, China | • Heating method: microwave heating | * Energy mode: full electric energy |

- Related information

Youshengda Microwave Technology (Shanghai) Co., Ltd Copyright ICP:2023002225-1 Disclaimer